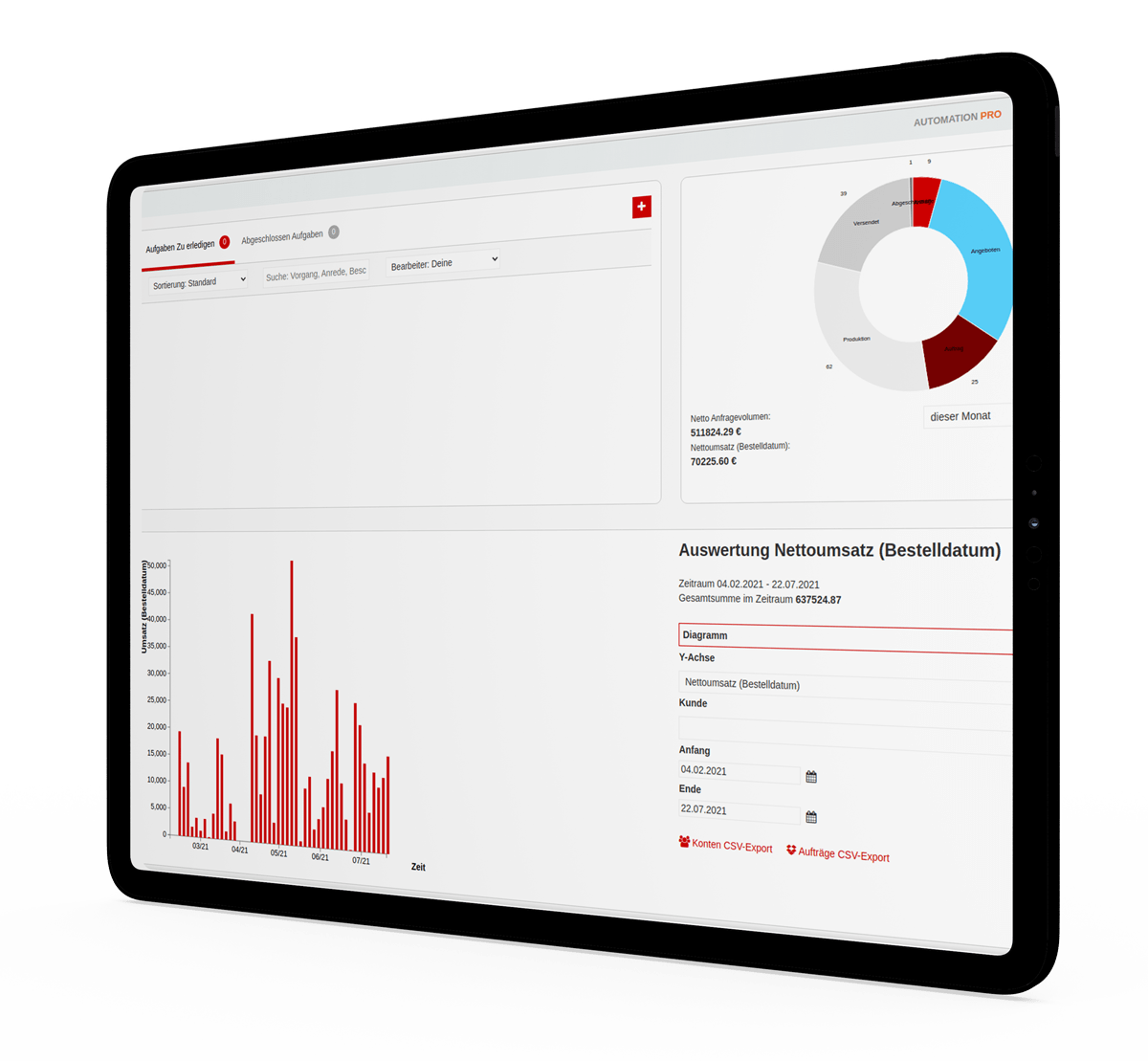

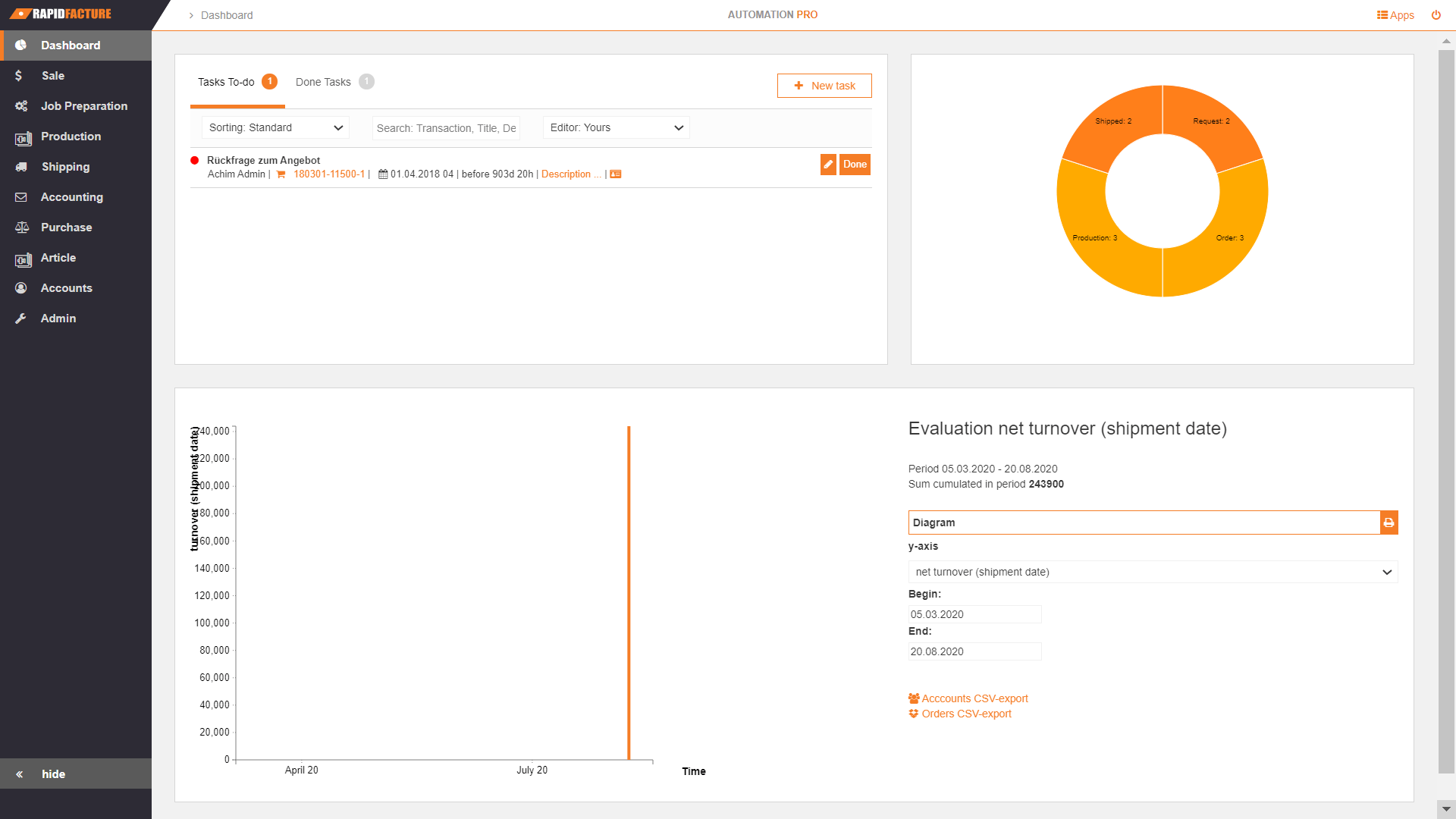

AUTOMATION PRO

Technologically revolutionary.Digitize all of your production processes with a single software solution. Save 75 percent time in calculations. Lower your costs and achieve efficiency benefits in the entire process chain with Automation Pro.

This is Automation Pro

Automation Pro is a modular system that is comprehensively designed to meet your business needs. Increase sustainability through transparency and achieve through highly efficient and intelligent process automation more sales.

Customers who go into the future with Automation Pro

INDUSTRY-SPECIFIC SOLUTIONS

Automation Pro is your solution

Production companies rely on tailor-made solutions in the entire value chain in order to operate quickly, sustainably and intelligently. Automation Pro accompanies you in your digital transformation. Offer a new customer experience in a changing market and react with flexible and automated processes.

Industry sectors

Automation Pro is the solution in many industries to make business processes sustainable and intelligent.

-

Welding and joining technology

-

Turning, CNC turning

-

Milling production, CNC milling processing

-

Metal and steel trade, material shop

-

Industrial manufacturing and manufacturing operations

-

Individually adapted to your industry

MANUFACTURING OPERATING SYSTEM

Why Automation Pro?

Lower your costs with Automation Pro and increase your sales. Save up to 75 percent time in the calculation and create a new customer experience through intelligent, sustainable and advanced algorithms. Transparency and control at every level. From customer inquiry to product delivery and beyond.

advantages

Unlimited potential thanks to state-of-the-art technologies

Digitize all processes

Digitize your company and increase business performance in the complete workflow, through automation and seamlessly connected processes./p>

Fast and profitable calculation

Save up to 75 percent time when preparing an offer for individual products from a quantity of 1 and improve customer satisfaction.

Profitable customer retention

Create a unique customer experience through relevant and intelligent methodologies along the entire value chain. Interact in a tailor-made way and put your customer at the center.

Plan machines efficiently

Increase your machine efficiency and ensure optimal production utilization by optimizing the use of the machines and reducing downtimes.

Product master data management

Improve your data quality through intelligent networking of processes and minimize your efforts throughout the chain.

Smart Procurement

Ensure a highly efficient procurement process in your company and make purchasing transparent and strategic.

functions

Powerful and convincing functions for your business model

Overview of the main functions

-

Dashboard

-

Statistics

-

Sale

-

CRM

-

Order Preparation

-

Production planning (rough planning, detailed planning)

-

Operations, manufacturing processes and work steps

-

Prooduction

-

Post calculation, work packages and time recording

-

Shipping, interfaces to shipping providers, tracking, hand scanner

-

Bilss

-

Purchasing

-

Goods Receipt

-

Inventory

-

Complaint Management

-

Article overview and material database

-

Company Database, Intelligent Tags System

Extremely fast in the calculation

Increase your company's efficiency with quick and reliable calculations for your customers.

FAST AND EFFICIENT

Modern technologies accelerate processes

Extremely fast in the calculation

Increase your company's efficiency with quick and reliable calculations for your customers.

Automated business processes that communicate seamlessly

Accelerate your throughput, increase your efficiency and create highly profitable automated

business processes.

UNRESTRICTED FREEDOM - ENTERPRISE - IOT - PLATFORM

production operating system

Automation Pro is a highly intelligent system and solution for companies in the digital age to meet individual business needs. With the seamlessly communicating processes based on Industry 4.0 technology, you create new and innovative standards (IoT platform). Automation Pro is the operating system of production in the future. The networking of the core tasks creates sustainability and a strong value-added chain even with a quantity of one.

Automation Pro helps you with your digital transformation.

Our software offers you powerful functions for the entire process. Right from the first customer contact, you focus on the customer and strengthen loyalty and trust. The system communicates at every level through AI-supported links. Management is carried out by a technological ERP system. Plan and manage all production processes digitally and react flexibly to customer requests. Increase transparency and reliability at every step. From customer contact, manufacturing, product delivery to customer care and loyalty.

Automation Pro is the enterprise IoT platform consisting of PPS, ERP, CRM, MES and tailor-made customer-based solutions for intelligent and automated manufacturing.

PRODUCTION PLANNING SYSTEM (PPS)

Production planning efficient from quantity 1

Reduce your throughput times through efficient planning, control and production monitoring with the PPS system. Thanks to intelligent and automated processes, you can meet production deadlines and increase your delivery reliability to your customers. Plan your production perfectly with exact material requirements planning and simultaneous capacity planning of the production steps in your production. The order monitoring supports production progress and the quality of the products to be continuously monitored until the general order release.

-

Production control and monitoring

-

Material requirements planning, time and capacity planning

-

Significantly reduce throughput times

MANUFACTURING EXECUTION SYSTEM (MES)

Management of complex manufacturing processes

Improve your performance in your production. Monitor and control complex manufacturing processes intelligently and automatically with the integrated MES system. Achieve significantly higher efficiency in your production and better quality in your products. Other functions include machine data acquisition (MDE), production data acquisition (BDE), detailed planning, traceability, performance analysis and document management.

-

Machine and production data acquisition

-

Performance analysis of production as well as rough and detailed planning

-

Product tracking and document management

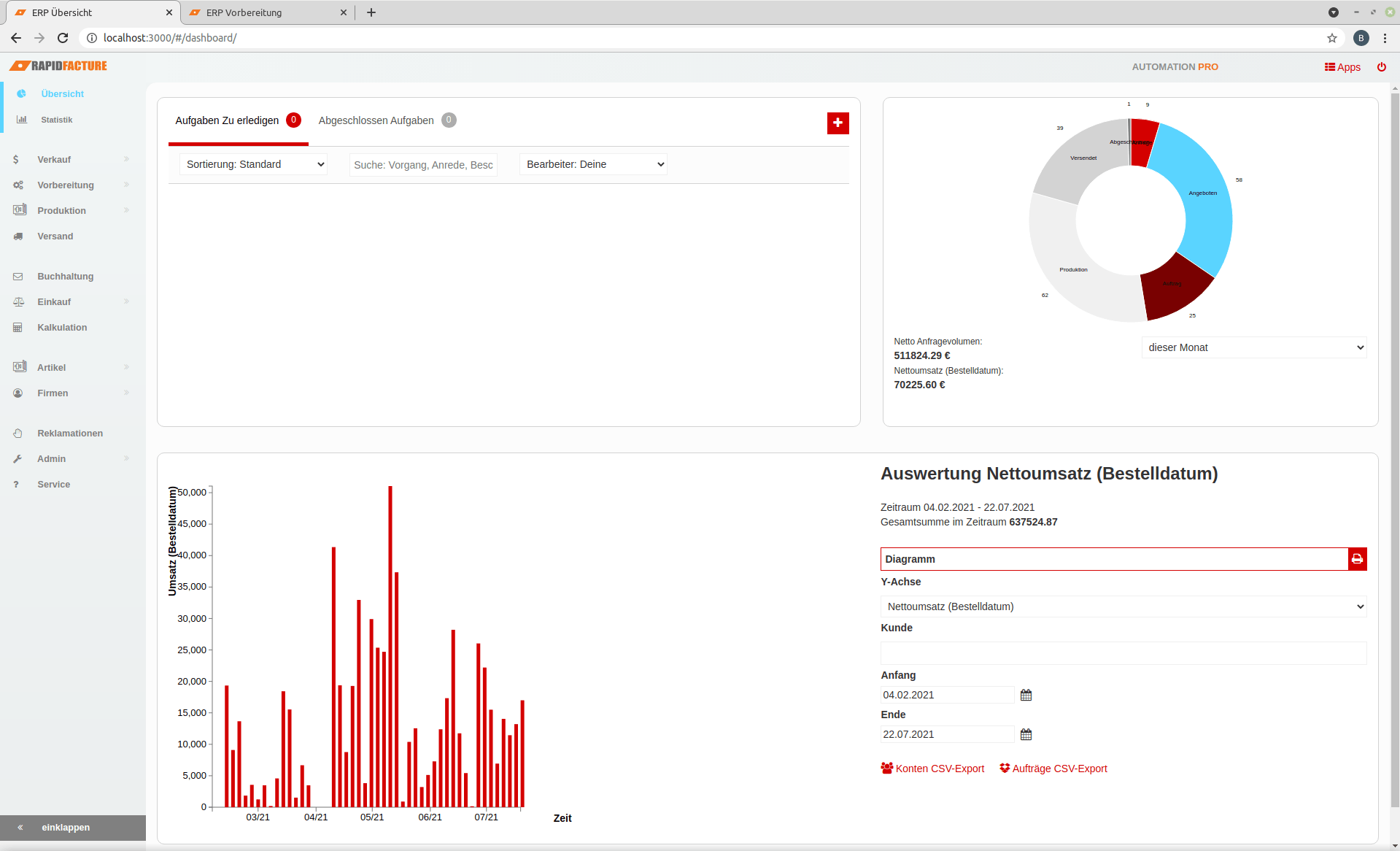

ENTERPRISE RESOURCE PLANNING (ERP)

Seamless networking of all processes

Plan and manage all the necessary resources in your growing company and control your business processes automatically with Automation Pro. Map the complete value chain. From purchasing, warehouse management, production, invoicing and shipping. With Automation Pro, all processes, company departments and system modules are seamlessly linked. This allows you to optimize your processes and improve transparency between the various processes.

-

Automation and control over your business areas

-

Material requirements planning, time and capacity planning

-

Growth oriented solution

-

flexibly adaptable to your requirements

CUSTOMER-RELATIONSHIP-MANAGEMENT (CRM)

For a first-class customer relationship

Improve your customer relationship management and increase customer lifetime value (CLV). Gain more trust through a first-class customer experience. Make it easier for your sales management to develop valuable strategies through specific customer data. Recognize the needs of your customers quickly and satisfy them uniquely and efficiently. Through the lead management process, you categorize from the first contact to the qualified customer and align your strategies gradually and intelligently.

-

First-class customer relationship management increases your returns

-

Tailored alignment of marketing strategies

-

Categorization and qualification of leads

NUMEROUS MODULES

Design Automation Pro individually and flexibly

Automation Pro is a modern and technological system. With increasing business demands in your company, you need to avoid process interruptions. Remedy this by integrating modules.

Automation Pro extensions

Modules at a glance

TYP

Module Name

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod

TYP

Module Name

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod

TYP

Module Name

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod

TYP

Module Name

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod

AUTOMATION PRO IS MOBILE

Desktop and Mobile

Automation Pro can be used on any end device without installation, regardless of whether it is a PC, laptop, tablet or smartphone. Central data management facilitates the exchange: work in the office or comfortably from your home office.

FAST AND RELIABLE

Private Cloud or On Premise

Decide which variant is most suitable for companies. Automation Pro runs professionally and reliably on both systems. We support you in your choice and analyze your requirements together with you in order to provide Automation Pro in the private cloud or as an on-premise solution with you as a server.

RF Private Cloud

Solution for most companies. High flexibility, scalability and tailor-made SaaS (Software-as-a-Service) solution. At the same time, the data is specifically assigned to only one customer.

On-Premise

The data is on-site on your servers. Your company provides the IT infrastructure and resources for the smooth operation of Automation Pro.

TECHNOLOGY OF TOMORROW

Highly flexible and high-performance

MIGRATION

Migrate to Automation Pro

Your existing ERP system can be migrated to Automation Pro. Many companies already have ERP systems. Most of these are rigid and are operated via isolated solutions. This reduces performance and growth in the company. We have already supported numerous such companies and made the switch to Automation Pro.

Contact us!

If you have any questions about our products, their implementation or integration, or your personal wishes.